Let’s Talk About Superwash

- Iris

- Jul 20, 2020

- 5 min read

Choosing yarn can be confusing. Here I spend a little bit of time helping you make the first decision, superwash or not? What does it mean, what is the impact of it on the environment, and do you really need it?

What is Wool?

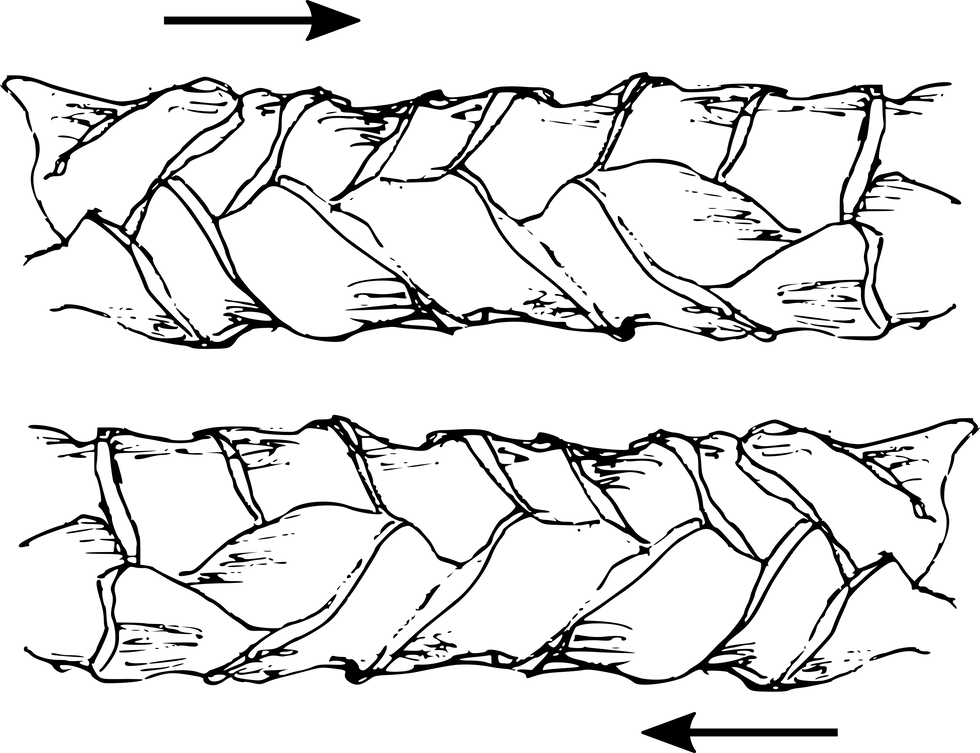

Wool is a natural fibre, and like human hair is predominately made up of a protein called keratin, you might have heard of this in all those magic hair treatments and skincare products. Essentially differences in the keratin protein and the arrangements of the proteins within the fibres are what makes fur or hair from different animals have different properties. If we take super close up images of these fibres using an electron microscope we can begin to appreciate these differences. The image below shows hair fibres from merino wool, angora rabbits, shahtoosh (a fine wool made from the hair of the Tibetan antelope) and human hair. As you can see each hair has ‘scales’ on its surface, the wide exposed end of these scales typically points to the tip of the hair away from the skin. This directionality of the fibres prevents friction between adjacent hairs and helps to expel foreign matter and dead skin from the pelt as well as spreading sebum (wool grease).

If you want to learn more about different kinds of fibres check out our “Fibres” post coming soon.

What is Felting and Why Does Wool Felt?

Felting is the process by which the loose structure wool fibres are compressed. This happens because the wool fibres are disorganised and the scales on their surface rub together and become entangled. Felting itself has many uses and is an ancient technique used to create a nonwoven fabric as well as cute 3D pieces, but why can it also happen to yarn?

In the process of making a material such as yarn, the fibres also become disorganised causing the scales to point in opposite directions. This leads to an increase in friction between the fibres as they rub against each other. This movement and friction is increased at high temperatures and with excess agitation and results in ‘felting’ of the yarn.

What does Superwash do to Wool?

Due to the tendency for natural untreated wool yarn to felt with high heat and agitation, like those experienced in a washing machine, the process of superwash was invented. The superwash process transforms the actual structure of the fibres in order to reduce the likelihood that they will undergo felting during a washing cycle. There are several ways in which this can be achieved, but all techniques focus on removing and/or softening the scales of the fibres. By removing the scales there is less surface area for the fibres to rub against each other in the yarn or fabric and thereby reduces the risk of felting. The image below shows a close-up view of untreated natural wool fibres on the left, and fibres that have undergone a superwash process on the right.

Chlorine-Hercosett Superwash Method

The Chlorine-Hercosett method is the most effective, cheap and popular superwash process with about 70% of all “machine washable wool” being treated with this method. In this process, the fibres are first treated with chlorine (bleach) which etches away the scales before being coated in Hercosett resin, a synthetic wax-like substance which reacts with the proteins in the wool and coats the surface.

Sounds Great, What’s The Problem With Superwash?

Let’s start with chlorine, chlorine is the major component of bleach, and I’m sure you wouldn't pour bleach on your plants. However, during the superwash process, large amounts of chlorine waste enters the water system where it reacts with other naturally present chemicals to form toxic and carcinogenic (cancer-causing) molecules, which are not only unsafe for humans but also pose danger to aquatic ecosystems.

Amongst these is a particular group of chemicals called dioxins, these are highly toxic and have been linked to reproductive and developmental problems, as well as causing damage to the immune system and increasing cancer risk. One of the main problems of dioxins is that they persist for a long time in the environment, where they enter the drinking water and food chain. The World Health Organisation suggests that “due to the omnipresence of dioxins, all people have background exposure”.

What about the Hercosett resin? This synthetic polymer is formed using highly toxic materials, which may put factory workers at risk if strict protocols are not followed, the resulting polymer is said to be safe and stable, like many other plastics, however, there is little information available on the safety of this polymer. Eventually, the resin will start to degrade and release microplastics into the water during washes. Microplastic pollution is on the rise and leading to vast disruption of oceanic ecosystems.

One of the final environmental concerns with the superwash process is the vast quantities of water that are required. In many regions across the globe, water security is incredibly important and the redirection and damming of rivers and water systems can lead to irreversible changes to local ecosystems.

Alternative Superwash Methods

This all sounds scary, and many in the industry have caught on to the issues surrounding the traditional superwash process and many alternative methods have been developed. These are broadly covered by three areas; altered versions of the original process which aim to reduce chemical use, alternative treatments such as enzymes, radiation or plasma, and the use of biological polymers such as chitosan extracted from shellfish.

However, along with their own environmental issues, all of these processes do not result in the same results as the Chlorine-Hercosett method and are typically more expensive and time-consuming, making them economically not viable.

Due to strict regulations put in place in many countries in regards to pollutants entering water systems, much of the superwash process now happens in countries with less strict regulations. This means yarns are shipped across the world to be processed, adding again to the environmental footprint of the yarn. It is also difficult to find information as to the nature of the superwash process that has been used for a given yarn and the country in which it has taken place.

Why You Don’t Need Superwash

Now let me convince you that you don’t need to worry about all of these superwash processes, because in reality for most of us producing our own garments it’s not needed.

Personally I have always preferred to knit and crochet with non-superwash yarns, the superwash process, as a trade-off for increased washability, removes many of the natural characteristics of the wool. Many superwash yarns have an almost squeaky nature when being knitted, an unnatural sheen, coming from the resins, and have lost the natural volume and fluffiness of the fibre.

The only difference you need to make when using non-superwash wool is to either hand-wash or wash your woollens on a gentle wool wash cycle. This change, I imagine for most of us will not be a change at all, as after spending countless hours on a gorgeous colourwork sweater I certainly wouldn’t be washing it on a hot, high spin cycle!

By making this simple change in your yarn buying habits you can do your small part to reduce your environmental impact and be rewarded with enjoying the unrivalled pleasure of the feeling of real natural wool. You’ll never go back.

Want to Learn More?

Thank you for reading all the way to the end of my article. If you are still interested in learning more about superwash or any of the topics covered here, I have provided links below to the sources used to carry out my research.

Yarnsub blog: A great trial of superwash and non-superwash yarns and how they stand up to the washing process. https://yarnsub.com/articles/fibers/superwash

Dioxins from the WHO: https://www.who.int/en/news-room/fact-sheets/detail/dioxins-and-their-effects-on-human-health

Detailed overview of various superwash processes: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6369147/

See also the Handbook of Textile Fibre Structure

Comments